If you want to know how does the dosing pump work and what are its specifications, then you’re at the right place. Let’s read to know all about it. The dosing pump is a device that helps to accurately dose chemicals into a process or system.

It accomplishes this by drawing fluid from a storage tank and then injecting it into the process at a specific rate. The dosing pump has many specifications that should be taken into account when selecting the right model for your needs.

Dosing pumps typically have a flow rate of 1-100 ml/min and can be used with liquids of all viscosities. In terms of specifications, dosing pumps usually have a pump head made of stainless steel or PTFE, and a volumetric accuracy of +/- 2%. Dosing pumps are widely used in many industries, including pharmaceuticals, food and beverage, and water treatment.

A Guide: How Does The Dosing Pump Work And What Are Its Specifications?

Dosing pumps are devices that are used to meter out precise doses of chemicals, supplements, or other materials. They have a wide variety of applications in many different industries. In this blog post, we will discuss how dosing pumps work and what their specifications are.

What Is A Dosing Pump?

A dosing pump is a type of pump that is used to pump water into a water purifier. This type of pump is often used in reverse osmosis systems, where it is used to pump water through a semi-permeable membrane.

The dosing pump is a key component in these systems, as it ensures that the correct amount of water is pumped through the membrane. Without a dosing pump, the reverse osmosis system would not be able to function properly.

In addition, to reverse osmosis systems, dosing pumps are also used in other types of water purification systems, such as ion exchange systems. In these systems, the dosing pump is used to pump water into an ion exchange column, where it exchanges ions with the column’s resin beads.

This helps to remove impurities from the water. Dosing pumps are an essential component of many different types of water purification systems, and they play a vital role in ensuring that these systems work properly.

How Does The Dosing Pump Work?

Without a doubt, water purifiers have become an essential part of our lives. They not only remove impurities and contaminants from our water, but they also help to improve the taste and smell of drinking water.

One key component of most water purifiers is the dosing pump. Dosing pumps are used to inject a measured amount of chemicals into the water, which helps to remove impurities and improve water quality. The number of chemicals injected into the water is controlled by the dosing pump, which ensures that the correct amount is always used.

Dosing pumps are typically powered by electricity, batteries, or solar power, making them extremely versatile and easy to use. Thanks to dosing pumps, we can enjoy clean, healthy drinking water on a daily basis.

Its Specifications

Dosing pumps are an essential part of water purifiers. They deliver a precise amount of chemicals, such as chlorine or ozone, into the water to disinfect it and make it safe to drink.

The dosing pump is a key component in ensuring that the water purifier is working properly and that the water is safe to drink. There are several important dosing pump specifications that need to be considered when choosing a water purifier.

- The first is the flow rate. This is the rate at which the pump can deliver the chemical into the water. It is important to choose a pump with a flow rate that is appropriate for the size of the water purifier.

- The second specification is chemical compatibility. This refers to the ability of the pump to handle different types of chemicals. It is important to choose a pump that is compatible with the type of chemicals used in the water purifier.

- The third specification is pressure. This refers to the amount of pressure that the pump can generate. It is important to choose a pump with enough pressure to deliver the chemical into the water at the correct concentration.

- Finally, it is also important to consider the warranty when choosing a dosing pump. This will protect against any defects in the pump that may occur during normal use.

FAQs: How Does The Dosing Pump Work And What Are Its Specifications

Q 1: How Does A Dosage Device Function?

A 1: A facility for the automated injection of chemicals into a wastewater network is known as a chemical dosing system. This technology is used to control septicity and odor emissions. Typically, pump stations, sewer manholes, and rising mains employ these systems. They can be set up anywhere odor containment is needed, though.

Q 2: How Many Different Kinds Of Dosing Pumps Exist?

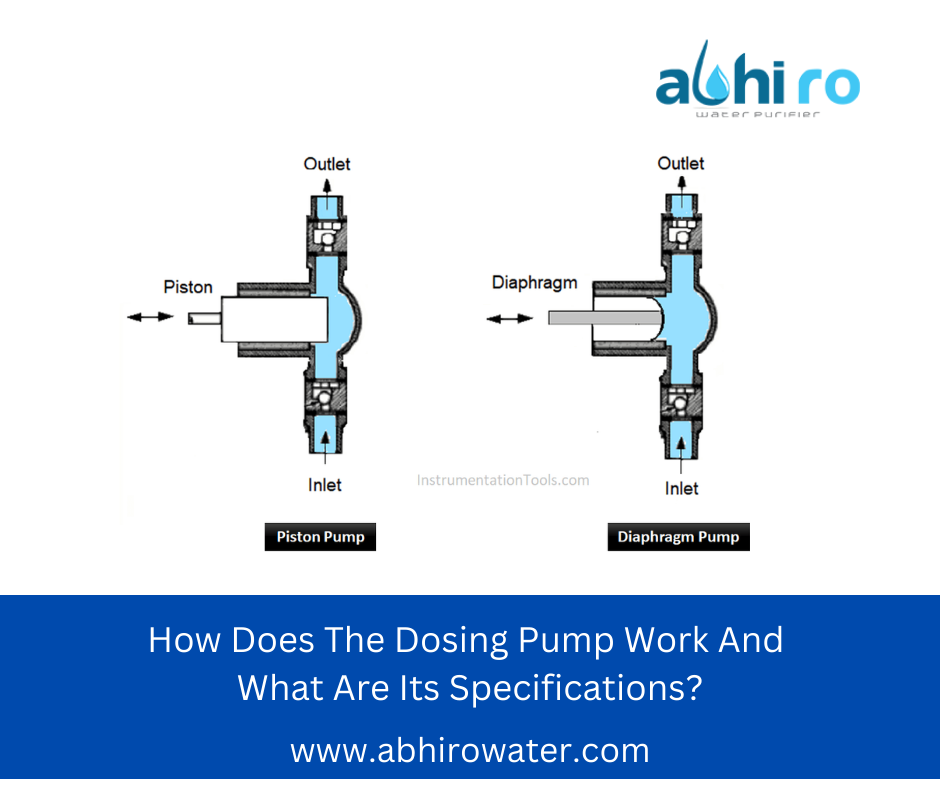

A 2: Based on its action and pumping mechanism, dosing pumps can be classified into 4 main categories: A piston fills and empties a pump chamber in a diaphragm-type constant injection pump.

Q 3: Why Dosing Pumps Are Used?

A 3: Numerous different applications call for the usage of dosing pumps. Pumps are mostly used to change the pH of the water and to prevent corrosion and precipitation. The pumps are frequently used to combine flocculants, scale inhibitors, and disinfectants. Of course, there are additional uses for the pumps.

Q 4: How Should A Dosing Pump Be Sized?

A 4: A metering pump should be sized keeping this in mind such that the highest projected flow rate is between 85% and 90% of the pump’s capacity, leaving room for additional capacity, if necessary. To guarantee the accuracy, the minimum capacity should never be lower than 10% of the pump’s capacity.

Conclusion

In conclusion, the dosing pump is a device that accurately dispenses measured doses of liquid. It has a wide range of specifications that make it an ideal choice for many different applications. Whether you need to dose chemicals, pharmaceuticals, or other liquids, the dosing pump is sure to get the job done.